Roller Dyno is a diagnostic tool specifically designed to measure the power of a lot of type of vehicles.

This one consists of four rollers, two each sides, to perform test for front and rear driven vehicles.

All dynos work to mimic load conditions by exerting brake forces on a motor. In roller dyno , one of the vehicle’s axis rests

on a roller that is used to measure the output power delivered to the wheels as horsepower and speed. This is convenient for

automotive testing because the vehicle can be set on the machine without removing the engine.

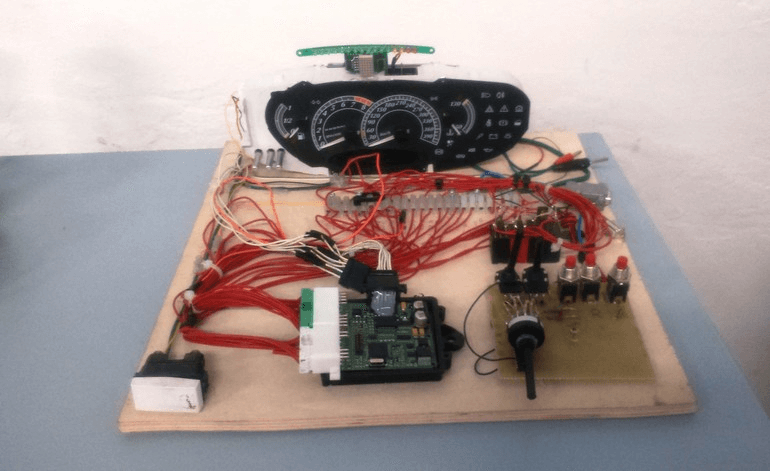

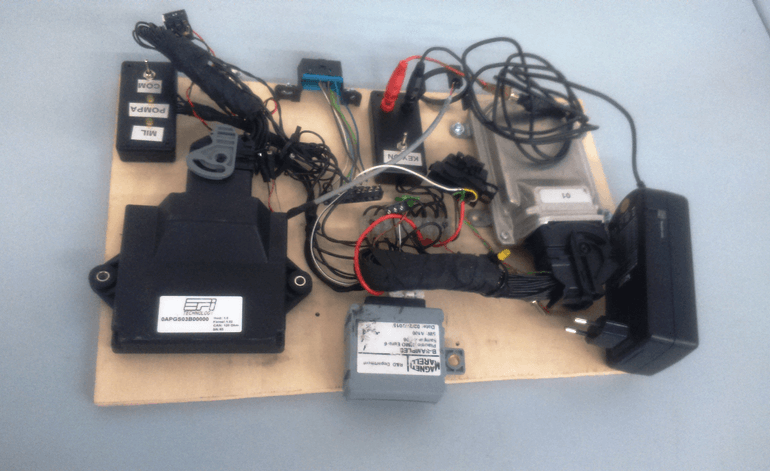

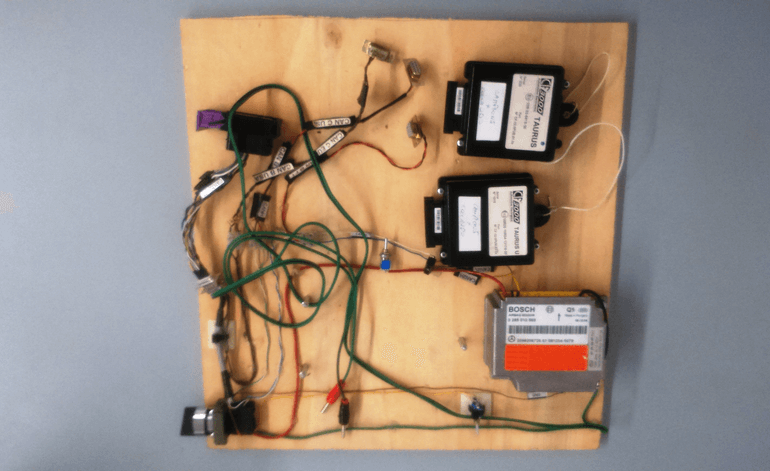

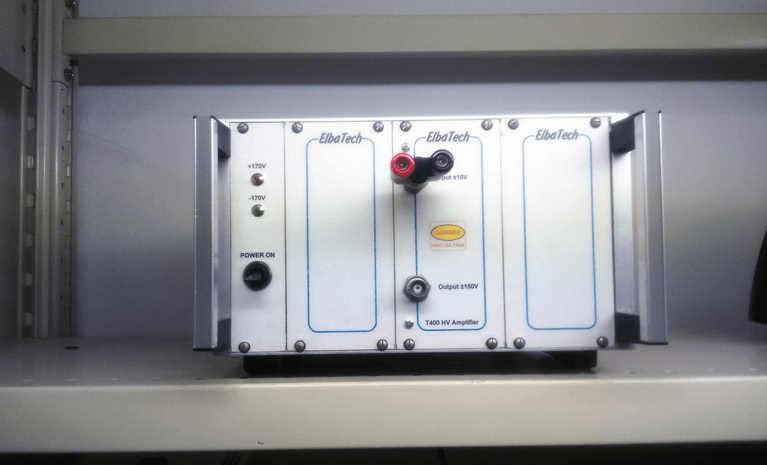

Simulates the engine in HIL(hardware in loop) mode. An HIL simulation include electrical emulation of sensors and actuators. These electrical emulators act as the interface between the bench simulator and the embedded system under test. The value of each electrically emulated sensor is controlled by the bench simulator and is read by the embedded system under test . Likewise, the ECU under test implements its control algorithms by outputting actuator control signals. Changes in the control signals result in changes to variable values in the bench simulator

• ECU test bench

• R&D wirings

• Diagnostics testers